-

-

Manufacturer ofCrushing MachineriesYour requirements will guide us

Manufacturer ofCrushing MachineriesYour requirements will guide us -

PremiumQUALITY RANGEwith perfection

PremiumQUALITY RANGEwith perfection

Welcome To PRABHU MUDRIKA ENTERPRISE

PRABHU MUDRIKA ENTERPRISE is pioneer in manufacturing all types of crushing equipments in India having well-equipped workshop with latest technologies deployed. Our tech-professional team is having indepth technical skills, sound experience and expertise especially in the field of Crushing, Screening, Grinding and Material Handling Equipments. A dedicated team for quality control is working round-the-clock for getting superior quality product.

Some of core crushing equipments manufactured by us are:

- Jaw Crushers

- Vibrating Screens

- Impactors

- Portable Loaders

- Hammer Mills

- Belt Conveyors

- Bucket Elevators, etc.

How do you select an optimal CRUSHER?

Selecting optimal crushing equipment can be difficult. Luckily, tools and software are available that simplify weighing different options and help make decisions. The backbone of all these analysesis careful calculations that take into account the capabilities and constraints of different crushers and operational requirements.

Every crushing site and operation is different, and the optimal results are normally obtained by combining theoretical conclusions with practical experience of different materials, operational conditions, maintenance needs, and economic aspects of various alternatives.

Below are some key issues listed according to crushing stages in brief. While defining the best technical solution for your requirements, it’s good to remember that many crushers are available not only as stationary but also as mobile or portable versions – in case you prefer to move or transport your crusher at the production site or between sites regularly

If you are interested in more detailed analyses tailored just for your crushing operations, please contact Prabhumudrika Enterprise. We have practical experience with thousands of different crushing applications around the world, and we are happy to help in find the equipmentthat best fits your needs

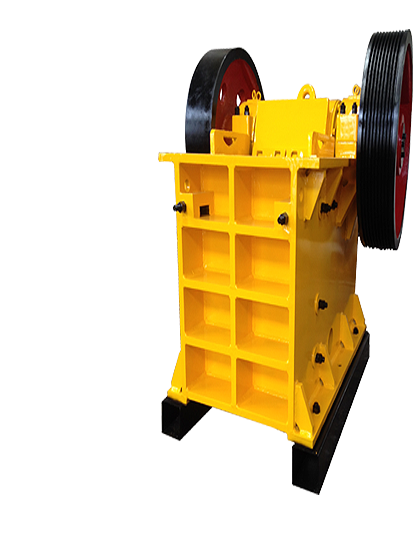

Primary Crushing with JAW CRUSHER

In terms of the size of the feed opening, the client gets a better return on investment when the primary crusher is a jaw crusher. That means less drilling and blasting because the crusher accepts larger boulders, The mechanical advantage of jaw crushers ensures efficient crushing of even the hardest rocks,One of the key advantages of jaw crushers is their ability to crush a wide range of materials, including hard and abrasive ones.

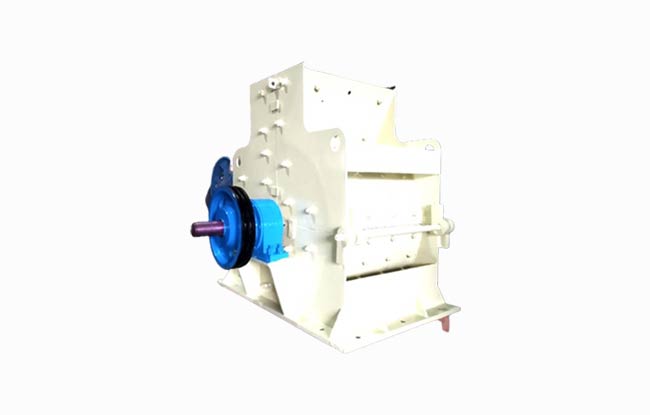

IMPACT CRUSHERS

Impact crushers are versatile crushing machines that can be used at any stage of the crushing process. However, the features and capabilities of different impact crusher types vary considerably.

Impact crushers are traditionally classified into two main types: horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. These different types of impact crushers share the crushing principle, impact, to reduce the materials to smaller sizes, but features, capacities, and optimal applications are far from each other.

Horizontal shaft impact (HSI) crushers are used in the primary, secondary or tertiary crushing stage. HSI crushers reduce the feed material by highly intensive impacts originating in the quick rotational movement of hammers or bars fixed to the rotor. The particles produced are then further fragmented inside the crusher as they collide against the crusher chamber and each other, producing a finer, better-shaped product.

CORE CRUSHING EQUIPMENTS

CRUSHING PLANTS

JAW CRUSHER MACHINES

VIBRANT SCREENS

GRIZZLY FEEDER MACHINES

BELT CONVEYORS

HORIZONTAL SHAFT IMPACTOR MACHINES, ETC

WHY

PRABHU MUDRIKA

ENTERPRISE ?

Ease of Operation

Low Power Consumption

Efficient Operating System

Minimal Maintenance

OUR PRODUCTS

WINNING

CLIENTS

DONE

EXPERIENCE

OUR CLIENTS